GC Gold Label Hybrid | GC Hybrid Bulk Fill Restorative GIC With Advanced Glass Hybrid Technology

Rs.3,275.00 Rs.3,700.00

Cash on Delivery (COD) Payment Service Available COD enabled for selected products only. If all items in your cart are COD enabled. The eligible cart value for COD falls within the Rs. 100 to Rs. 10,000 range.

Save Rs. 500 Discount on order above Rs 20,000

Save Rs. 200 Discount on order above Rs 10,000

Save Rs. 100 Delivery charges on orders above Rs 5,000

Description

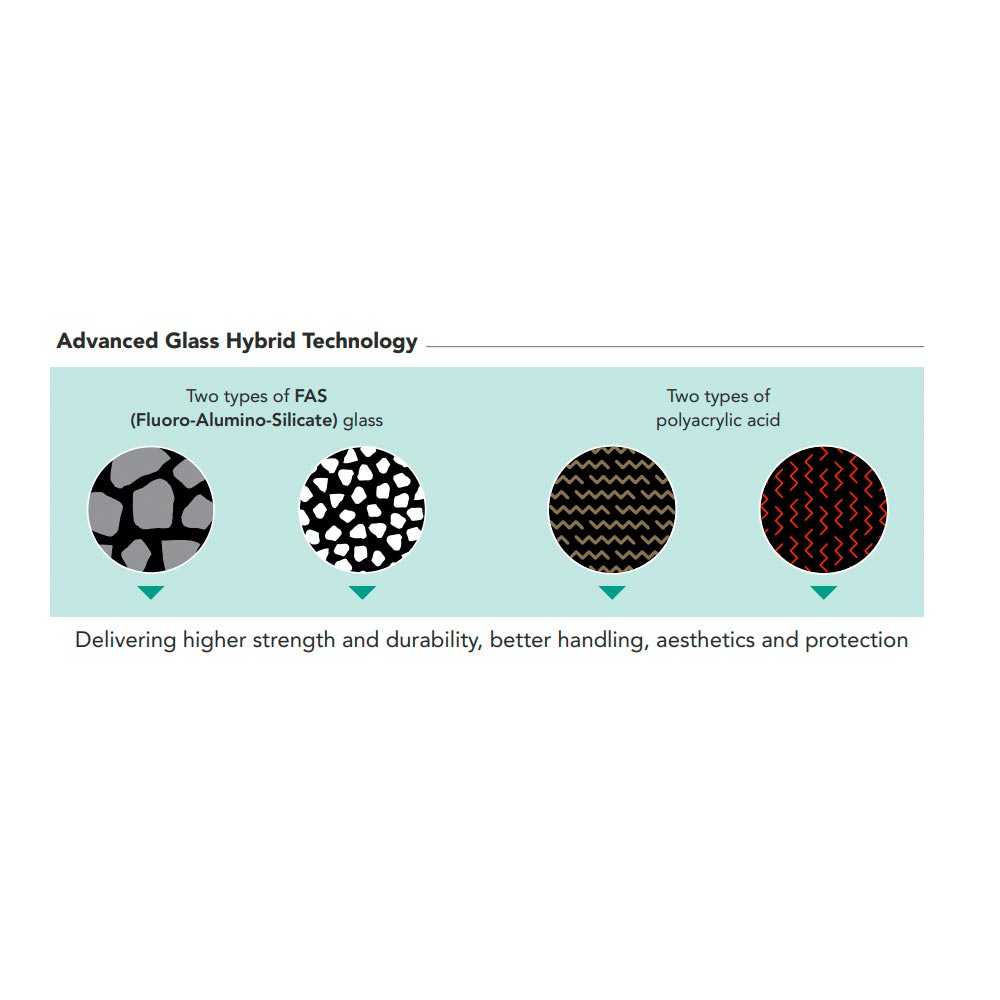

GC Gold Label Hybrid is a hand-mixed, self-adhesive glass ionomer restorative formulated for posterior applications. Powered by GC’s Advanced Glass Hybrid Technology, it combines two types of Fluoro-Alumino-Silicate (FAS) glass and two types of polyacrylic acid to deliver improved strength, acid resistance, and clinical handling.

A smart particle size distribution contributes to enhanced mechanical strength, while finer FAS glass particles reduce light scattering for better translucency and visual integration with surrounding tooth tissue. The formulation promotes a high fluoride release profile and improved acid resistance, supporting long-term performance and protection in challenging oral environments.

| Brand | GC |

|---|---|

| Features | #. High mechanical strength for posterior restorations #. Improved translucency for better shade matching #. Enhanced acid resistance due to advanced FAS glass and polymer formulation #. Effective fluoride release #. Moisture-tolerant during placement #. Suitable for bulk fill applications |

| Indications | #. Class I and Class II restorations in deciduous teeth. #. Non-load bearing Class I and Class II. #. Intermediate restorative and base material for heavy stress situations in Class I and Class II cavities using the #. Class V and root surface restorations. #. Core build-up. |

| KEY Specifications | Powder/ Liquid Ratio (g/g) - 3.0/1.0 STORAGE : Recommended for optimal performance, store at temperature of 4-25°C (39-77°F). |

| Directions To USE | #. #. #. #. #. |

| Packaging | 1 x 15g Powder 1 x 6.4mL Liquid |

|---|